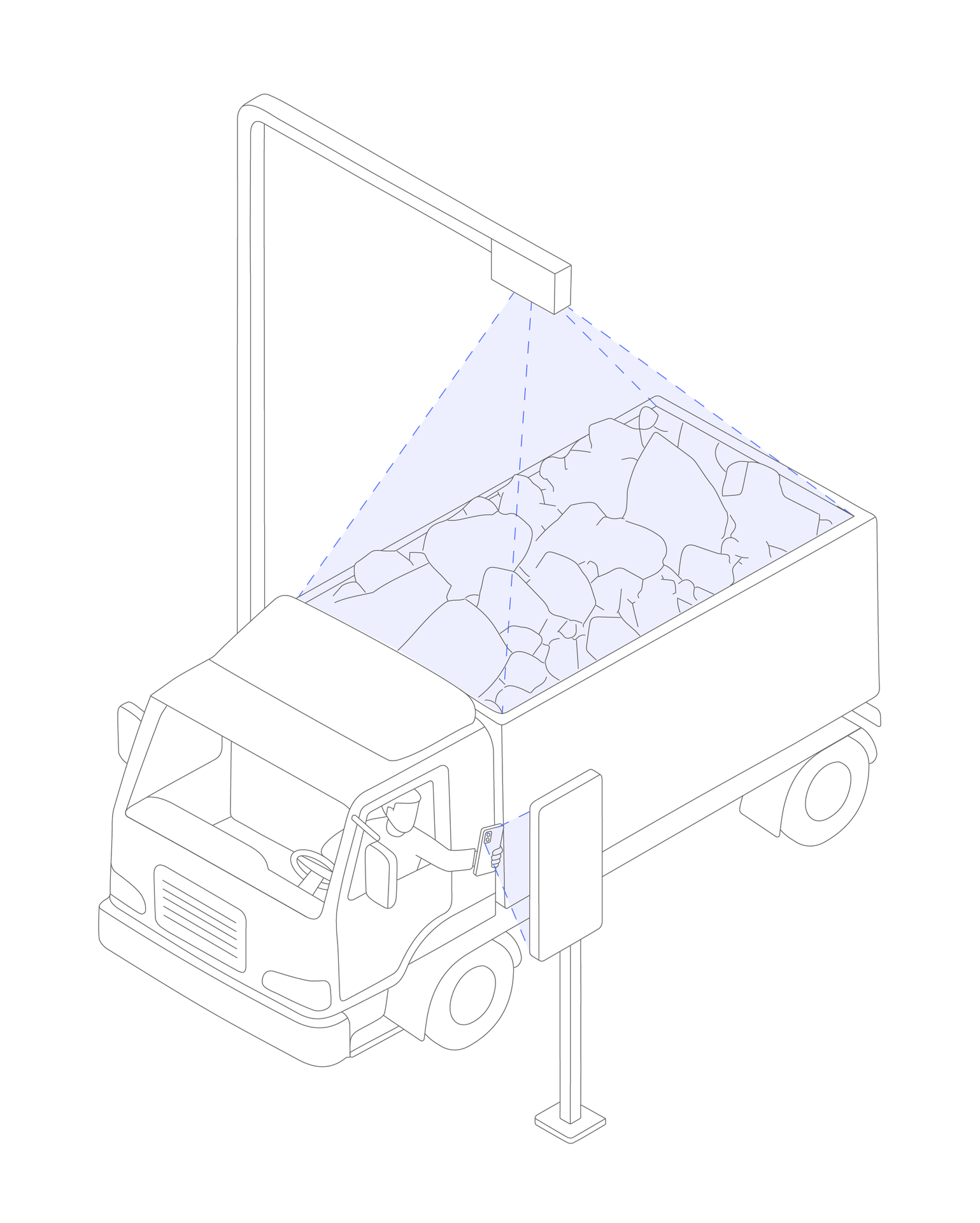

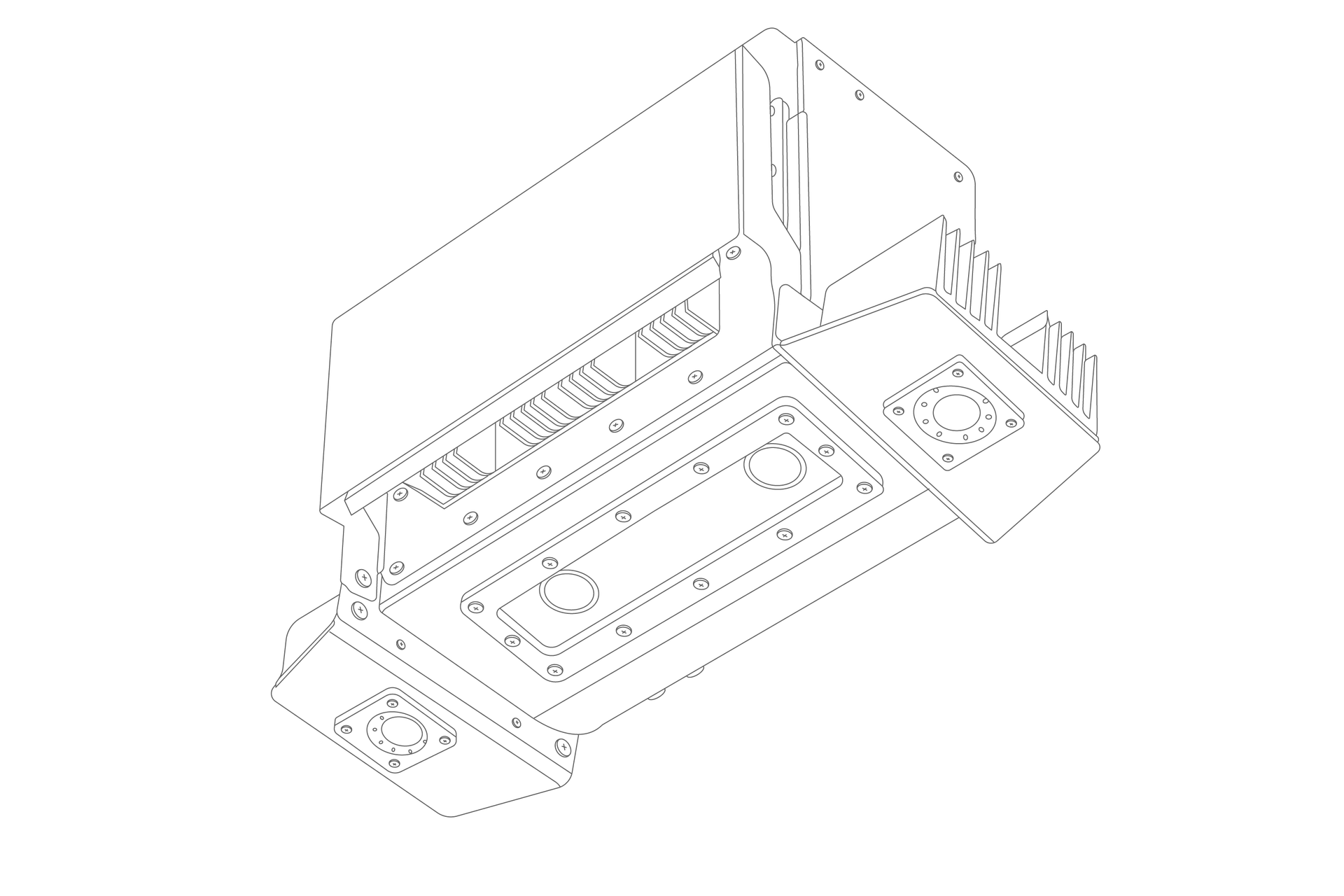

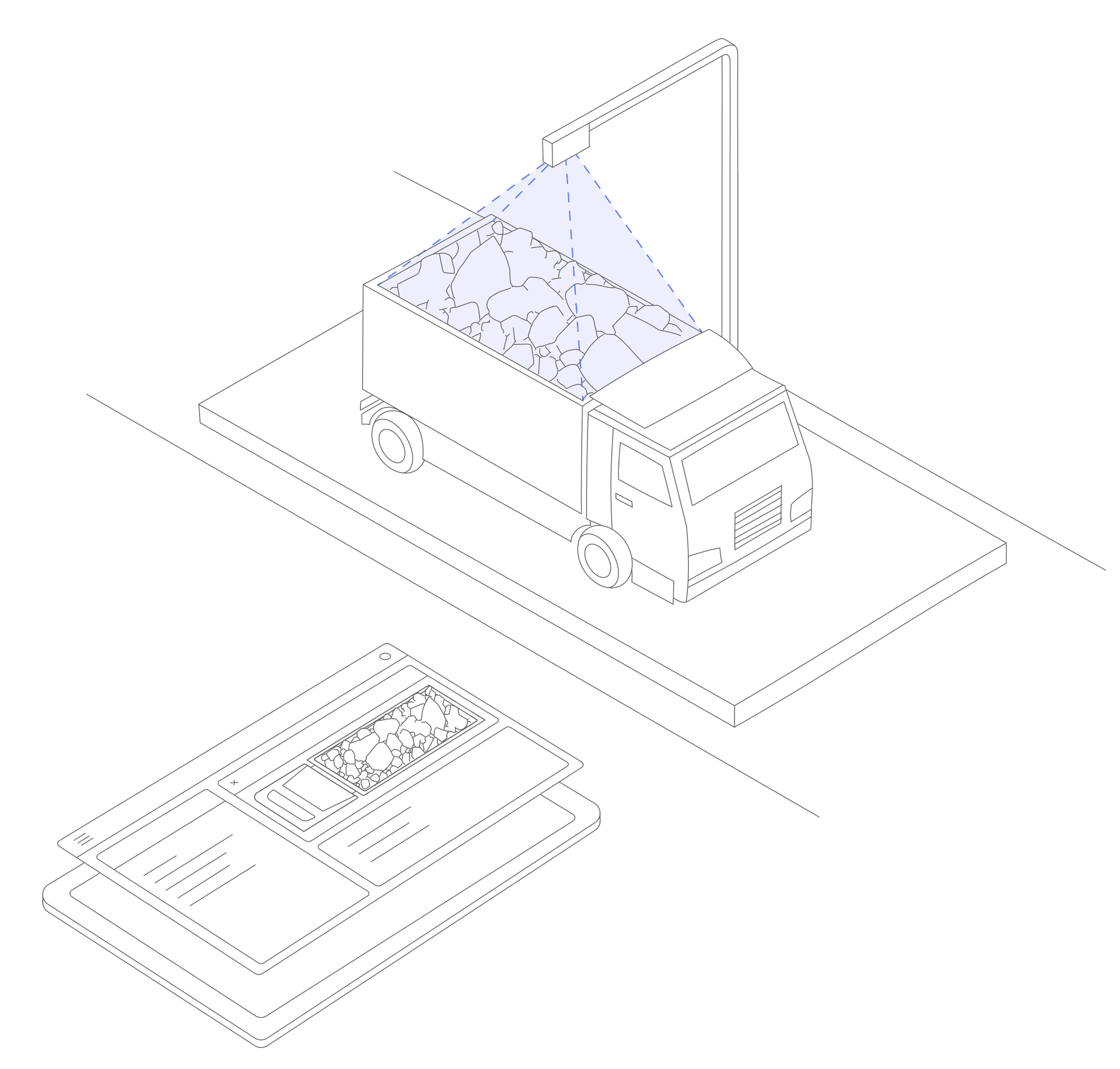

Truck Imager

Transparency at the scale. Identify material flows upon arrival.

Everything worth knowing about the deliveries: fully automated and in real time. The Truck Imager scans the load directly at the weighbridge or in the entrance area. No more discussions or subjective estimates.

Belt Imager

Efficiency on the line. Continuous quality control of the material flow for maximum value creation.

The Belt Imager shows exactly what is moving. Our AI-powered detection precisely identifies which material is on the conveyor belts. This knowledge enables active optimization of processing to extract the maximum from the material.

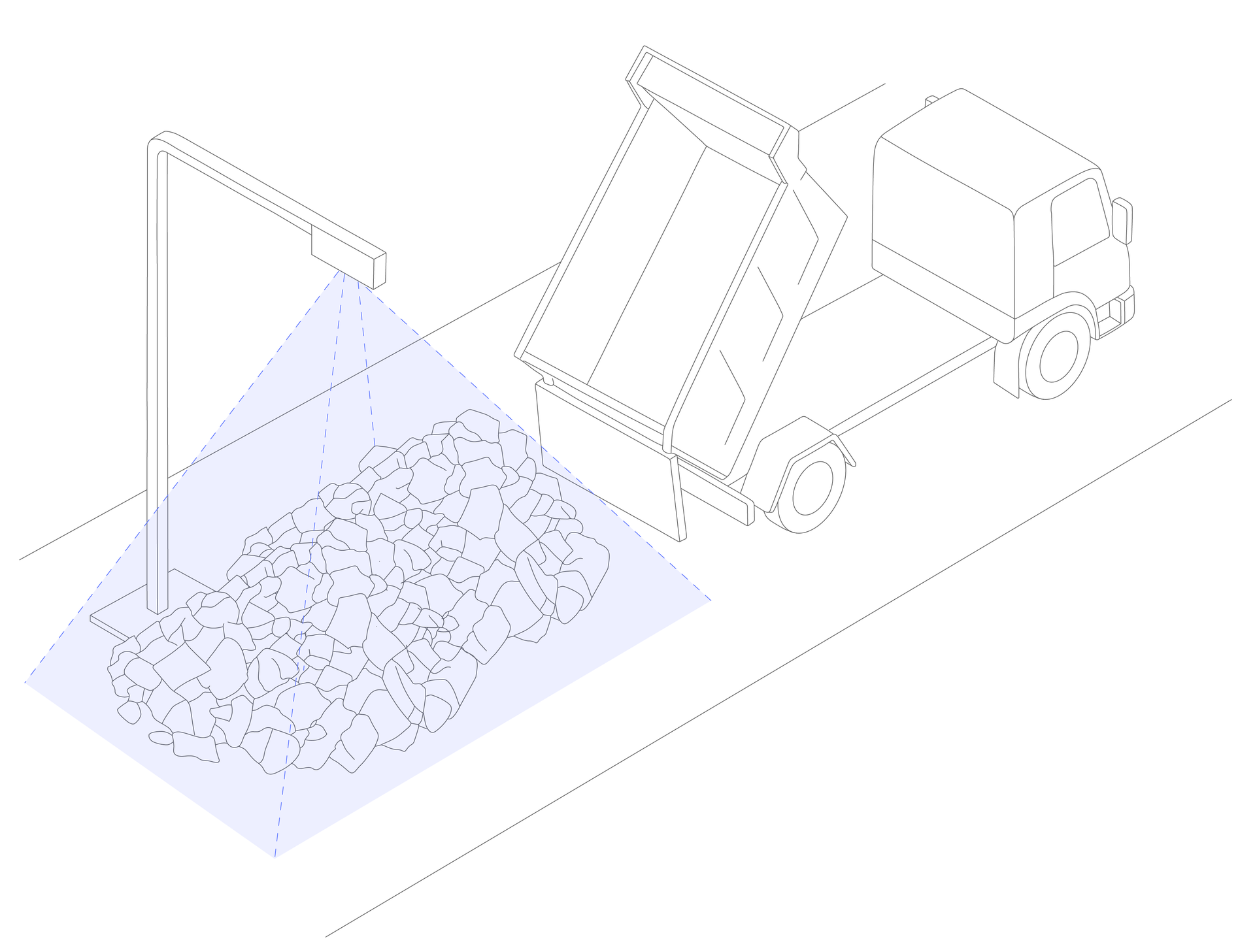

Heap Imager

My Heaps don't lie. Precise volume and material analyses in real time.

The Heap Imager looks closely when the material is most visible: during the unloading process. It analyzes the flow of material in motion as it is tipped from the truck or wheel loader. This also allows for the detection of contaminants that were hidden within the load.

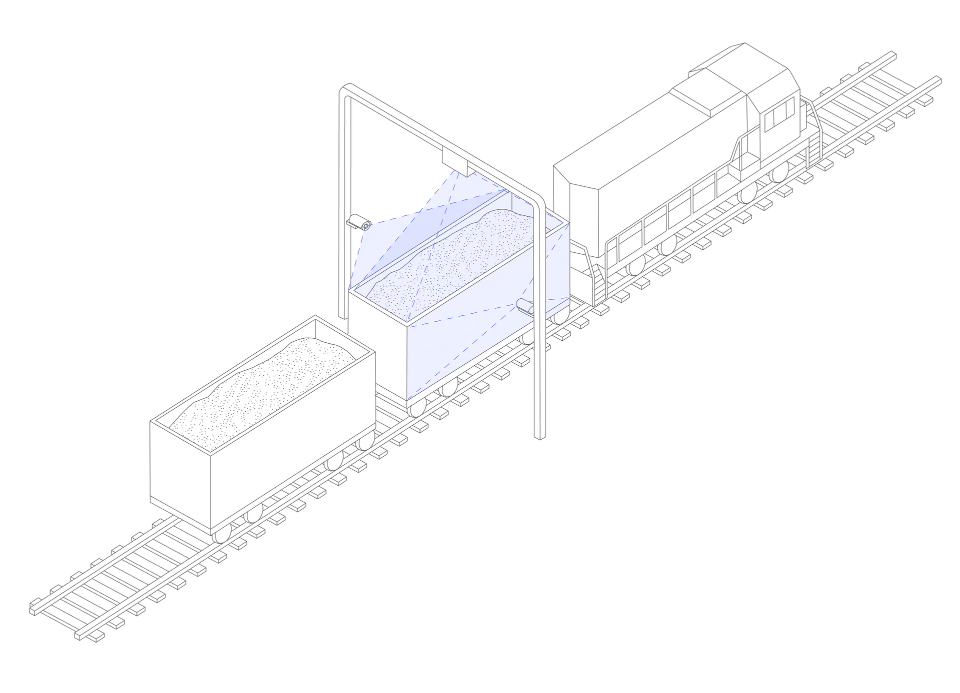

Train Imager

Rail logistics. Keep an eye on car conditions and cargo.

The Train Imager automatically captures both: the condition of the wagon and the loaded material. It documents every entry seamlessly while passing through. This saves manual inspections in the track area and provides immediate objective data for dispatch and quality assurance.

Self Scan

Delivery via app. The digital gateway for drivers.

The Self Scan turns the smartphone into a terminal. Through an intuitive web app, drivers independently navigate the process: from scanning the QR code to the AI check to the digital delivery note. Tedious office paperwork and long waiting times at the weighbridge are eliminated.